It’s something you lose sleep over and hope will never happen: a fire roaring through your building. While every facility professional will do what he or she can to ensure that a fire never begins in the first place, the next step is knowing how to minimize its spread.

Most people are familiar with the basics of fire suppression (sprinklers, fire extinguishers, etc.), but the passive fire protection that actually contains a fire at its point of origin can be invisible and nearly forgotten - until the day you come to truly appreciate and depend on it.

Passive fire protection (PFP), despite its name, is always at work.

Based on compartmentation of fire and preventing collapse through structural fire resistance, when properly installed and maintained, your building’s passive fire protection can save lives and assets, and the building itself.

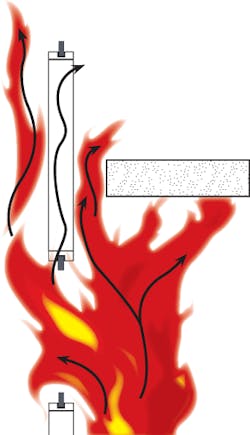

This diagram highlights the paths of fire propagation through improperly sealed wall penetrations. COURTESY OF IFC

Areas of Passive Fire Protection

According to Chris Jelenewicz, engineering program manager at the Bethesda, MD-based Society of Fire Protection Engineers (SFPE), there are four main areas of passive fire protection.

1. Structural fire protection

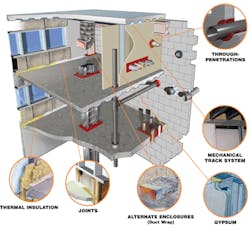

Structural fire protection guards essential structural components (such as structural steel and joint systems) from the effects of fire.

This is accomplished with a fireproofing material (spray-on thin-film intumescents, endothermic materials like gypsum-based plasters and cementitious products, mineral wool wraps and insulation, and fireproofing cladding) or building the structure out of concrete products.

“When structural fire protection is designed and applied properly,” says Jelenewicz, “the building’s structural integrity should be maintained when it’s exposed to fire.”

2. Compartmentation

Fire barriers, firewalls, fire partitions, and smoke barriers are all included in compartmentation.

Fire barriers include fire-rated walls, floors, and ceilings (often made of concrete, combination wood, gypsum, or masonry). These barriers are used to limit the spread of fire in a building and allow safe egress. Walls extend from a fire-rated floor to the fire-rated ceiling above, and continue into concealed spaces for full protection.

Bill McHugh, executive director at the Chicago-based Firestop Contractors Intl. Association (FCIA), also groups firewalls with structural protection. “These walls are built structurally stable, so even if there is collapse of a building on either side of the wall, the wall will remain standing,” he says.

John P. Sinisi, education committee chairman at the Cleveland-based Intl. Firestop Council, notes the importance of properly maintained fire barriers. “Rated walls and floors protect evacuation routes from fire and smoke migration,” he says, adding that the window of evacuation time is maximized when the barriers effectively contain the fire.

3. Opening protection

Fire doors and windows are installed in an opening of a fire barrier to maintain its fire resistance. McHugh explains, “Doors, builders’ hardware, and frames work together to form an effective smoke and fire barrier.”

Fire-rated glazing/glass and framing are tested as a complete assembly that maintains the protection of the fire barrier. Additionally, fire and smoke dampers (often used in duct systems) are considered “opening protection” and complete the fire barrier where air ducts penetrate fire-rated and/or smoke-resistant assemblies.

4. Firestopping materials

These materials are used to limit fire spread through penetrations in a fire barrier. “It’s not uncommon to see a fire barrier penetrated during a minor building alteration, and then the penetrating item isn't protected by firestopping,” says Jelenewicz. Electricians, plumbers, communications engineers, etc. can leave hidden holes in the barriers as they perform their services.

Stefan Juli is director of business unit chemicals at Tulsa, OK-based Hilti Inc., a member of both the IFC and FCIA. He says that membrane penetrations are problematic because, “if you have a fire, and smoke gets in a chase wall, smoke can easily go upward and actually spread through the building.”

If the penetration isn’t properly sealed and protected with an appropriate firestop system, the fire barrier is rendered less effective, and fire will spread beyond the compartment of origin.

Other areas of PFP that warrant mentioning are cable coating (the application of fire retardants to wire and cable), joint systems (which include changes in direction between fire-separating elements and the spaces surrounded by those elements), and perimeter fire barriers (which deal with the perimeter of the floor and the exterior curtainwall).

While passive fire protection can successfully prevent the spread of fire, it’s important to note that most professionals recommend redundancy in fire protection.

Related: Your Fire Safety System Could Be Falling Short

In other words, a fire-sprinkler system, alarms and detection systems, and occupant education, in conjunction with passive fire-protection systems, are a safer, more balanced approach to protecting your building and the people inside.

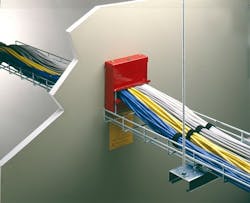

Make sure the firestop assembly you choose is appropriate for the penetration. COURTESY OF WIREMOLD/LEGRAND

Codes and Testing/Certification

A potentially complicated aspect of PFP is the bevy of codes and regulations involving each component of a fire-protection system. It’s vital to understand that a particular product (a window, for instance) isn’t fire-rated in and of itself - it’s rated only when it’s installed properly and used in a fire-rated assembly or tested system.

McHugh remarks that, unless you’re missing your building’s construction documents, knowing what’s required (and where) isn’t difficult. “On construction documents, fire-resistance-rated walls are [indicated],” he says, adding that the life-safety drawings included with construction documents make it clear where you need fire-rated components.

Keeping in line with National Fire Protection Association (NFPA) and Intl. Code Council code requirements is a matter of following these life-safety documents to see if you’re in compliance, and then maintaining those fire compartments.

Products within PFP systems are tested and certified to standards written by accredited organizations (including West Conshohocken, PA-based ASTM Intl. and Northbrook, IL-based Underwriters Laboratories Inc.).

Systems are rated by the half-hour or hour (the “F” rating), by temperature (the “T” rating), and by smoke penetration (the “L” rating). Some systems even have a “W” rating, which indicates the ability to temporarily resist water leakage prior to fire.

COMMON EXAMPLES of PASSIVE FIRE PROTECTION. COURTESY OF SPECIFIED TECHNOLOGIES INC.

Maintaining Your PFP

Along with knowing the codes and ratings associated with each PFP system in your building, constant and thorough maintenance is also important. “Building owners and facility managers are important stakeholders in a building’s fire-protection program,” says Jelenewicz.

“As such, they should play an important part in every phase of building modification to ensure that life safety is not impacted," he continues. "This includes the planning, design, construction, and maintenance of the building.”

If part of your building is rewired or plumbed, or if new communications systems are added, chances are good that penetrations have been made in fire barriers.

“Workmanship, odd opening sizes, missing caulk, spackled pipe penetrations, and top-of-wall conditions could all be signs that firestopping has not been addressed,” says Sinisi, who adds that existing construction always provides a unique challenge.

“Structures with installations older than 10 years rarely have any firestop installed, and contain unprotected penetrations. A mixed bag of contractors, service professionals, and installers working in your building all need to be educated, monitored, and held accountable,” he says.

If you’re not sure how a building change will affect your PFP systems, don't hesitate to seek answers from professionals. “When performing building modifications - even the most simple of alterations - make sure the modifications don’t impact the integrity of your existing fire protection," says Jelenewicz. “When in doubt,” he adds, “consult with your fire-protection engineer.”

McHugh advocates continual testing and vigilance. “Look at a fire door every time you walk through it,” he says.

“Make sure the fire-rating label’s not painted, make sure [the door] swings properly, and make sure it latches. If it doesn’t work, [fix] it. And, every time you walk through a fire-resistance-rated wall, think, ‘If it’s gypsum drywall or concrete block, does it have a chunk out of it?’” Sinisi provides the following questions to ask when assessing your facilities’ firestop:

-

Where are there rated walls and floors in your building?

-

Are the penetrations and tops of walls sealed?

-

If sealed, what tested system design was used for the repair?

-

Does the repair match the tested system design detail?

The bottom line: Know what’s going on in your building, and keep your eyes open for any changes in the fire-protection system that could weaken its efficacy.

Electricians, communications engineers, and plumbers can all leave unprotected penetrations in your fire barriers. COURTESY OF SPECIFIED TECHNOLOGIES INC.

Costs in Perspective

Another bottom line that’s constantly on the mind of facilities professionals, like it or not: money. How much is it going to cost to protect your building from fire spread? “Effective fire- and smoke-resistant compartmentation is a very interesting discipline to quote costs for,” says McHugh.

Because many older buildings already have some compartmentation, finishing the compartmentation can be done effectively, with costs depending on the quantity of mechanical, electrical, and plumbing items routed in the building and penetrating fire barriers. In common new construction projects, though, costs seem to be relatively negligible.

“Since there is already labor used to install the walls, doors, seal holes, etc., the incremental cost to move from non-resistance-rated construction to rated construction is minimal in comparison to the cost of the complete structure,” states McHugh.

Ultimately, you can’t afford not to have adequate passive fire protection. The price of saving lives, property, and assets is incalculable. Life safety should be your No. 1 concern.

If the worst happens and a fire breaks out in your building, your due diligence will pay off when the fire is contained - people will have time to evacuate, and you will be back in business much sooner than if no protection was in place. If keeping your fire-protection system balanced and well maintained is top of mind, worrying about fire spread won’t be.

At the time of this article, Jenna M. Aker was the products editor for Buildings magazine.Two hand-picked articles to read next: