The Where, What, and Why of Thermal Insulation Systems

Today’s thermal insulation systems offer a wide spectrum of options to conserve energy and protect the environment while insulating the building’s tenants from heat, cold, and moisture. To choose the best for your needs, it’s important to understand the where, what, and why of modern materials.

The Where

Insulation can occupy four spaces in a roof system:

Above the deck and membrane

Above the deck, but below the roof membrane

Within the deck

Below the deck

Materials often dictate the best placement in the roof system. Today, plywood and OSB have displaced the heavy T&G timber decks due to their lighter weight and cost-effectiveness. For the most cost savings, install non-structural fiberglass batt insulation beneath the deck, between the wood rafters. This design, coupled with thermal insulation beneath the deck, works in mild climates, but in colder areas, placing insulation beneath the deck exacerbates the thermal variation from day to night and summer to winter, which then magnifies the expansion and contraction of the roof system and the deck itself. It’s also trickier to seal the laps of a flexible vapor retarder between the roof rafters.

The What

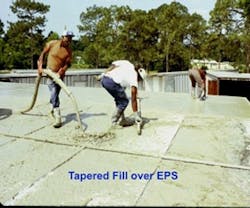

Other options evolving in recent years include embedding the insulation within the deck, such as expanded polystyrene boards set in a slurry of lightweight insulating concrete. This choice is frequently selected because the concrete topping can be tapered to the drains. Another popular version is the cementitious wood fiber deck, which combines the functions of an acoustical ceiling, thermal insulation, and structural deck. Modern versions of this include the cement-wood fiber deck, which is factory-laminated to polyisocyanurate or polystyrene foam insulation. Sandwich constructions can also include a core of foam with metal or other skins.

A membrane roof system can be coupled with extruded polystyrene foam insulation on top of the membrane, followed by heavy ballast (such as pavers or coarse river-rounded stone) to hold the foam insulation in place. These protected membrane assemblies, or PMRs, do just that – the insulation physically protects the roof membrane against impact and abuse, and it also reduces the thermal swing, since the insulation is on top. This system is especially effective in extremely cold climates where the construction season is short, since the membrane can be completed while the sun is shining, and the insulation and ballast can follow later even if the weather turns cold and wet.

A newer version of the protected membrane roof is the vegetated roof system. As with the other PMRs, the waterproof membrane goes down first, followed by drainage courses, filter fabric, and the vegetative growth medium.

The Past

Today’s choices are a far cry from the monolithic cast-in-place concrete, heavy timber, or poured gypsum roof decks that surfaced in the 1940s.

Concrete’s great mass provided insulation value due to the thermal lag of the concrete itself, and ASHRAE took this lag value into their design considerations. The boards of a heavy timber roof deck insulated a structure in the same way a log cabin is self-insulating. With gypsum, a form board made of glass fiber, gypsum, asbestos-cement, or mineral fiber would retain the gypsum while it cured and added a little extra R-value to the poured gypsum decking.

By the 1950s, steel was readily available. Its high strength and lower weight permitted a lighter-weight foundation and structure, making it quite cost-effective. Because the steel decking was fluted to provide deflection resistance, it was necessary to overlay the deck with a leveling board to bridge its ribs. These boards were called “thermal insulation,” but the typical R value of a 1-inch layer of wood fiber, foamed glass, glass fiber, or perlite was only around 2.78, certainly inadequate by today’s energy standards.

The Why

Fire resistance is a top concern for any roofing system. The combination of wood fiber insulation and a bituminous roof system may not meet FMGlobal Class 1 requirements. If the deck is gypsum or concrete, this would be no problem. With cellular plastic foams such as expanded polystyrene, it may be necessary to use an approved thermal barrier, such as perlite board or gypsum board. If styrene boards are encapsulated in lightweight insulating concrete, combustibility is no longer a factor.

When the urethane industry developed polyisocyanurate foams, also known as polyiso or iso-board, to replace the earlier urethane boards, it no longer needed the gypsum underlayments or composite boards of perlite or fiberglass to meet Class 1. This would be typical of roof systems today, where the isoboard can be directly attached to a steel deck, followed by an asphaltic roof membrane.

Many roof systems use gypsum boards or high-density isoboard materials as an overlay. In this case, it may be possible to apply a torch-down polymer-modified roof system since the overlay board serves as the fire barrier and protects the isoboard. Overlaying foam insulations with high-density board greatly improves the hail resistance and traffic resistance of the roof systems.

The menu of material and location combinations is enough to make the selection process seem daunting. But most of the underlay and overlay boards on the market today help protect the thermal insulation. That leaves the insulation to do the job it’s made to do – insulate.

Richard (Dick) L. Fricklas was technical director emeritus of the Roofing Industry Educational Institute prior to his retirement. He is co-author of The Manual of Low Slope Roofing Systems and continues to participate in seminars for the University of Wisconsin and RCI Inc. - The Institute of Roofing, Waterproofing, and Building Envelope Professionals. His honors include the William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.

Tips for Selecting Rigid Roof Insulation

The best roof insulation choice meets thermal needs, energy codes, and performance requirements, resulting in a roof system that performs well over the long term.

The Importance of Existing Insulation Technology

Insulation is, through its consistent and persistent performance, one of the most important components in a building when it comes to reducing energy costs and reducing carbon footprints.

Wet Insulation: Problems and Solutions

Wet insulation can cause myriad building problems – from troubles with structural integrity to issues of energy efficiency and occupant health.

About the Author

Richard L. Fricklas

Richard (Dick) L. Fricklas received a Lifetime Achievement Award and fellowship from RCI in 2014 in recognition of his contributions to educating three generations of roofing professionals. A researcher, author, journalist, and educator, Fricklas retired as technical director emeritus of the Roofing Industry Educational Institute in 1996. He is co-author of The Manual of Low Slope Roofing Systems (now in its fourth edition) and taught roofing seminars at the University of Wisconsin, in addition to helping develop RCI curricula. His honors include the Outstanding Educator Award from RCI, William C. Cullen Award and Walter C. Voss Award from ASTM, the J. A. Piper Award from NRCA, and the James Q. McCawley Award from the MRCA. Dick holds honorary memberships in both ASTM and RCI Inc.