Look up. Chances are good that the lamps illuminating this very page are fluorescent. More than two-thirds of all commercial and industrial facilities in the United States had installed fluorescent lighting by the 1960s, according to Advanced Lighting Guidelines: 2003 Edition, a document prepared by the White Salmon, WA-based New Buildings Institute.

The popularity of fluorescent lighting isn't surprising. No offense to Edison, but the inventors of this technology found a whole new way to brighten spaces with many fewer watts. The U.S. Department of Energy reports that fluorescent lighting can provide the same amount of illumination as incandescent lamps while using 25- to 35-percent less energy. The life of a fluorescent lamp is 10-times longer, too.

Despite all that is good about fluorescent lighting, early applications were plagued by flickering, buzzing, and an unflattering blue-green cast of light. Good news, though: "Fluorescent technology, over the past 10 to 15 years, has evolved dramatically in efficiency, longevity, color rendering, and even in issues of operations and waste disposal," says Randy Burkett, president and design principal, Randy Burkett Lighting Design Inc., St. Louis.

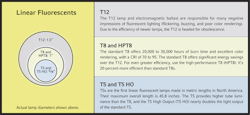

Fluorescent Lamp TypesT12 Lamps

The T12 (a 12/8- or 1.5-inch-diameter lamp) was the lamp of choice for many years—until a slimmer, more efficient lamp emerged. While these lamps are rarely specified in new construction today, they haven't reached extinction yet. "I can't remember, in the past 5 years, when we've even specified a T12 on new construction for buildings. It'll probably be a dinosaur in just another few years, and the only reason it's not now is that there are still a great deal of them out there in existing facilities," says Burkett.

Areas of the country with relatively low energy prices (by comparison) may be keeping the T12 market alive. "In places like the Midwest, where they have mostly coal-fired electric-generating power plants, the utility rates are very low. Although the national average is about 10 cents per kilowatt-hour right now, you can find places in Indiana where they're paying 3 or 4 cents per kilowatt-hour. For building owners there, it's been uneconomical for them to retrofit," explains James R. Benya, principal, Benya Lighting Design, West Linn, OR.

The use of T12 lamps has declined for two primary reasons: First is their relative inefficiency; second, funding and incentives shortened the payback period for replacement projects. "Utility companies were providing demand-side management rebates and incentives to replace old T12s and magnetic ballasts with T8s and electronic ballasts, and that was really effective in bringing everybody up to a new level of performance," says Mark Loeffler, associate director, atelier ten, New Haven, CT.

Technology advancements in the forms of improved (rare-earth) phosphors and electronic ballasts resulted in a T8 lamp-ballast system that provided better color rendering, longer life, and improved efficiency. These features made what was previously the workhorse of commercial lighting—the T12—a less desirable lamp. Despite the smaller diameter of the T8 (8/8 or 1 inch), switching from T12 to T8 lamps is relatively simple. According to Loeffler, retrofit is easy because T8 lamps fit into the standard socket configuration of T12 luminaires, and lamp length is the same.

T8 Lamps

As use of the T12s started to wane in the 1990s, the T8 rapidly became the most commonly used lamp in North America. Building owners and facilities professionals like its efficiency and long life. "T8 lamps can last anywhere from 20,000 to 30,000 hours," says Burkett. Architects and lighting designers appreciate the lamp's slim profile. "T8 lamps are smaller in diameter, and architects were happier because they could do more interesting, smaller-fixture housings," notes Loeffler. As pendant fixtures became more popular, the T8's size meant that indirect luminaires didn't have to be "surfboards hanging in the air," he jokes.

T8 lamps render colors better than most of their fluorescent predecessors, too. Unlike the majority of T12s that provide poor color rendering, the color rendering index (CRI) for most T8s is somewhere between 70 and 95 (the higher the number, the better; the maximum CRI is 100). A range of correlated color temperatures (CCTs), from 2,700 Kelvin (a yellow light) to 4,100 Kelvin (a more white or blue light), provides a broad spectrum of whites—ranging from warm to neutral to cool. Where color matching is especially important, 800 series T8 lamps are ideal. These triphosphor lamps provide above-average CRI.

High-performance T8 (HPT8) lamps—also known as super T8s—offer even greater energy efficiency than standard T8s. According to Madison, WI-based Focus on Energy, a high-lumen, long-life T8 lamp and low-watt electronic ballast generate the same total light output as a regular T8, but use less energy. "The super T8 is about 20-percent more energy efficient than the regular T8. That's a big difference," says Benya. Focus on Energy also points out that HPT8 lamps are extended-life lamps, typically rated to last 4,000 hours longer than standard T8 or T12 lamps. That could be up to 2 years in a normal office setting. New versions of T8 lamps that are hitting the market in 2008 promise 30,000 to 60,000 hours of life, meaning that these lamps will last as long as their light fixtures.

T5 Lamps

The newest member of the linear fluorescent family is the T5. This lamp's diameter (at 5/8-inch) isn't the only size differentiator between it and T12s or T8s. "[T5] lamps are not a full, exact 24-, 36-, or 48-inches long; they're actually somewhat smaller because they were made for metric fixtures," says Loeffler.

As the New Buildings Institute explains in Advanced Lighting Guidelines, retrofitting from T12s (or T8s) to T5s is often impractical because:

-

They offer little to no efficacy over T8 lamps.

-

Their metric lengths and lamp-holder design require significant changes to existing fixtures.

-

The T5's "substantially higher tube luminance is likely to cause glare problems in existing lighting equipment where the lamp can be viewed directly, even through a lens or diffuser."

It's best to use T5s in fixtures designed specifically for them. They are used in a wide range of interior and exterior fixtures including troffers, wallwashers, decorative luminaires, ceiling cove applications, and suspended direct or indirect lighting.

T5 High Output (or T5 HO) lamps nearly double the light output of standard T5s. "A T5 HO produces about 70- to 80-percent more light than the standard T5, yet, if you have them side by side on your desk, without reading the label, you wouldn't know the difference—they're identically shaped lamps. It's just done through the electronics," explains Burkett.

Greater light output is a plus. According to Eric Strandberg, commercial electric lighting specialist at Seattle-based Lighting Design Lab, "One advantage that T5 High Output has is that it's roughly the same lumen output as two T8s or two T12s, so once you go to a T5 HO, your lamp count can go down."

A word of caution, though: Because T5 HO lamps are so bright, glare can be problematic. "There's so much brightness in such a small-diameter lamp, and if it's not well diffused or somehow camouflaged, the brightness of the lamp can be almost painful," says Loeffler. T5 HO lamps should be used in either suspended indirect fixtures or direct fixtures in high-bay applications.

Compact Fluorescent Lamps

Wall sconces, pendants, downlights, and table and floor lamps are ideal applications for compact fluorescent lamps (CFLs). CFLs can replace incandescents that are roughly 3 to 4 times their wattage, saving up to 75 percent of the initial lighting energy, according to the U.S. Department of Energy's Energy Efficiency and Renewable Energy (EERE) office. Both the energy savings that result and their long lives offset the significantly higher cost of CFLs. The EERE office reports that, while you can expect to pay 3- to 10-times less for comparable incandescent lamps, CFLs last 6- to 15-times as long. "A standard light bulb might be anywhere from 1,000 to 2,000 hours. Compact fluorescents are going to be 10,000 or 12,000 hours," Strandberg explains.

Early models, marketed in the 1980s, were noisy and provided poor color rendering and slow start-up; manufacturers have worked hard since then to remedy these problems, but to employ CFLs effectively, you should be aware of their limitations. These lamps may not operate well at certain temperatures. According to the U.S. EPA's ENERGY STAR® program, extreme temperatures can affect CFLs. Some CFLs can be used outside in temperatures down to -10 degrees F. and up to 120 degrees F., though, when it's very cold, they may take longer to reach full brightness. Read the manufacturer's specifications carefully: Some lamps may not operate well—or even operate at all—when used outdoors.

Strandberg offers more words of advice to avoid misapplication: "They also don't work very well in fixtures that were designed around a directional light source, like a spotlight or a floodlight." Use CFLs where they work best. According to the ENERGY STAR program, open fixtures that allow airflow enable CFLs to perform better.

The first CFLs targeted the retrofit market. "Integral lamp-ballast combinations with screw-in Edison bases provided convenient and inexpensive alternatives for lamps used in hotels, apartment complexes, schools, and other long burning-hour applications," explains the New Buildings Institute in Advanced Lighting Guidelines. Because these are self-ballasted, the ballast is disposed of with the lamp when it's spent. While the energy savings and long life are definite advantages, these self-ballasted, screw-in CFLs are not as efficient as pin-based CFLs. Despite this, screw-based CFLs remain the best choice when trying to maximize energy efficiency in historic fixtures.

In commercial applications, pin-based CFLs are the clear choice over their screw-in counterparts. "If you buy a regular incandescent downlight and screw a compact fluorescent in, it will work much worse than if you bought a compact fluorescent downlight with a pin-based lamp," says Benya. These lamps have a rated life of between 10,000 to 12,000 hours and offer significant energy savings over incandescent and halogen sources.

Maintenance Considerations

Maximize Lamp Life

Selecting the best lamp and ballast combination for your application can dramatically reduce the maintenance required. For example, by installing lamps with a long life, fewer replacements are necessary, saving on time and labor. Long lamp life and infrequent relamping are especially important when lighting areas that require special lift equipment to access fixtures (e.g. an atrium).

Lamp life may also be affected by lamp and fixture capability. The misuse of CFLs is a prime example. "Incandescents really aren't susceptible to heat problems, whereas a compact fluorescent might overheat inside a recessed can and shorten its life," explains Burkett.

Selecting the right ballast is equally important in reducing maintenance and maximizing lamp life. "We had a job where the fluorescents kept going out. Finally, we figured out that they put the wrong ballast in," explains Katherine C. Abernathy, principal lighting designer, Abernathy Lighting Design Inc., North Providence, RI.

While lighting controls reduce wasteful operation by turning lights off in unoccupied areas, selecting the most appropriate ballast in these applications is necessary to prevent premature lamp failure. Berkeley, CA-based Lawrence Berkeley National Laboratory (LBNL) recommends using rapid-start ballasts when the average "on" time for lamps is under 3 hours per start. There are a few drawbacks, though: Rapid-start ballasts are 5- to 10-percent more expensive than instant-start ballasts, LBNL explains, and are not as efficient, either. "The vast majority of ballasts out there are going to be instant-start ballasts. They cost less and they also use a little less power. But, with instant-start, if they're turned on and off a lot during the day, then it's hard on the lamps and they fail sooner," says Strandberg. Rapid-start ballasts (especially programmed-start rapid-start ballasts) are ideal because, according to Advanced Lighting Guidelines, they minimize cathode deterioration. "The way they turn the lamp on is much gentler on the lamp," Benya explains.

Once you've purchased the most appropriate lamp and ballast, make sure they are both installed properly. "If the lamp isn't clicked into the sockets right, it can burn for awhile, but it tends to short arc and will shorten lamp life," adds Abernathy.

Control Light

Fluorescent lamps are ideal for applications that control light via timers, occupancy sensors, and daylight photosensors. As a result, lamps are operated less, energy is saved, and the frequency of relamping decreases. "Depending on the application, occupancy sensors can be a good way to lengthen those maintenance cycles," says Strandberg.

Dual switching is another lighting-control strategy (although it's less sophisticated). The basic principle is that one luminaire housing multiple lamps and ballasts has two manual switches. For example, one switch will control two of the three lamps, and the other switch will power the remaining lamp. With both switches on, the space is illuminated by all three lamps. "If you have a lot of daylighting coming in during the day, you may only need one lamp on. Then, as the sun goes down, you may need two lamps; at night, you may need three, depending on your task," explains Abernathy. "It's poor-man's dimming."

Of course, the simplest way to curb wasteful lighting is with the flick of a switch. "Simply turn lights off that don't need to be on," Loeffler states. Encourage building occupants to help you in this quest. In October 2007, in recognition of Energy Awareness Month, BOMA Intl. issued advice to property managers on how to save energy. Of the 10 suggestions provided, No. 1 was to create awareness among tenants by promoting energy-saving goals and some tips to reach them.

Group Relamp

Spot relamping, the practice of replacing lamps one at a time as they expire, can become a tiresome task for maintenance professionals. As the ENERGY STAR program points out, this method for lamp replacement wastes valuable labor. Since the expense of labor far exceeds the price of fluorescent lamps, group relamping may be a more cost-effective strategy. "With the use of group-relamping procedures, all of the lamps in an area are installed at once and then, at a predetermined interval, all of the lamps are replaced before they start burning out on a regular basis," explains Strandberg. Group relamping enables maintenance staff to schedule a time that's least disruptive to building occupants and work efficiently with equipment and supplies in tow. Another benefit of group relamping, according to the ENERGY STAR program, is the reduced cost of lamps, because they can be bought with bulk-purchase discounts and less storage space is needed for the replacement lamps. Evaluate staff resources to see if group relamping makes sense. "If you've got a huge building, then group relamping is usually more economical," Benya says.

To determine when to perform group relamping, find the rated life of the lamp and calculate the typical hours of operation. "At 100 percent of the rated life of the lamps, which is typically 20,000 hours or more, 50 percent of the lamps will fail," explains Benya. "The most economical point to group relamp is around 70 percent of the rated life of the lamps."

Replace Lamps with the Same Bulb

Using the wrong lamp in a fixture can result in shortened lamp life and generate complaints from occupants about glare and insufficient light levels. To avoid these problems, pay close attention to the diversity of lamp types being specified during the design or retrofit of a lighting system. Spaces with too much variety, such as an office that uses T8, HPT8, and T5 lamps, can cause confusion among maintenance employees, who may inadvertently install the wrong equipment during relamping. Fewer types of lamps can also alleviate other headaches, too. "[Lighting designers] have to play a compromising game to make sure they're not going to drive the building managers crazy when stocking lamps," adds Loeffler.

If lighting professionals have provided a manual explaining what equipment is used and where, refer back to it when any component of the lighting system needs to be replaced. "When the light does burn out and they replace it, they've got to replace it with the same bulb," says Abernathy. Opting for cheaper lamps may save a few dollars initially, but can compromise energy efficiency and the quality of light. As an example, Abernathy explains that a less expensive, easier-to-find CFL may cast an undesirable bluish light, contrasting with the CCT of surrounding lamps. It can also be tempting to replace screw-based CFLs with incandescents because it's easier, quicker, and dramatically cheaper - a practice the New Buildings Institute calls "snap back." The bottom line: The manual is provided so that replacement lamps can be selected to meet the original specification, so use it.

Lamp DisposalRecycle or Dispose of as Hazardous Waste?

Despite all the things facilities and lighting professionals love about fluorescent lamps, there is one undesirable characteristic: the mercury they contain. The light produced by a fluorescent tube is caused by an electric current conducted through mercury and inert gases, according to the DOE's EERE office. Mercury is a neurotoxin known to cause kidney and brain damage. Efforts made by the lighting industry to address concerns about disposal and the risk of mercury from lamps leaching into soil and water are commendable. According to the Rosslyn, VA-based National Electrical Manufacturers Association (NEMA) in a September 2007 release, manufacturers have reduced the amount of mercury in their fluorescent lamps by more than 90 percent.

In 1995, the EPA issued the universal waste rule to address many hazardous wastes that were previously discarded in the trash (e.g. fluorescent lamps). According to the organization, the rule is designed to reduce hazardous waste in the municipal solid waste (MSW) stream by making it easier for universal waste handlers to collect these items and send them for recycling or proper disposal. To determine if a fluorescent lamp is hazardous, a Toxicity Characteristic Leaching Procedure (or TCLP) test is performed. Advanced Lighting Guidelines explains that lamps that pass the TCLP test aren't considered hazardous waste and don't require special disposal procedures, except in states where more stringent regulations than federal law are mandated.

Unfortunately, there has been some dispute about how low-mercury or TCLP-compliant lamps actually pass the test. According to the Boston-based Northeast Waste Management Officials' Association (NEWMOA), some manufacturers use additives to influence the TCLP test and mask the true mercury content of the lamp. The organization also indicates that the TCLP test is irrelevant for lamps burned in an incinerator; all of the mercury content of those lamps will be released into the atmosphere. For these reasons, the NEWMOA says it's best to handle all mercury lamps, including those that pass TCLP, as hazardous or universal waste. This is good advice, considering that mercury vapor is released into the air when fluorescent lamps are tossed into a dumpster.

Options for disposal include recycling or taking spent lamps to a designated drop-off point in your area.

Lamp recycling is increasing rapidly. In September 2007, NEMA reported that lamp recycling had increased from 70 million lamps in 1997 to 156 million lamps in 2005. "Lamp manufacturers are all very aware of the environmental impacts of their products and have a long history of being environmentally conscious and responsible; everybody advocates recycling fluorescent lamps, not just to sequester the mercury, but also to reclaim the metals and even the glass from the lamp," says Loeffler. Recycling isn't costly, either. The cost of recycling, according to NEMA, represents only 1 percent of the total costs of owning a fluorescent lamp.

With light-emitting diode (LED) technology on the horizon, you may be wondering how long fluorescent lighting will remain the most effective means to illuminate commercial environments. "I think it's fair to say that fluorescent lamps, especially the linear fluorescent, will probably be the last source that will be influenced by LEDs with respect to one-for-one replacement, especially in general lighting. LEDs do not have the output at this point, and probably won't for the next decade or so, to challenge a fluorescent in light output," says Burkett. "Fluorescent is a very efficient source, and will still be a workhorse for years to come."

Jana J. Madsen ([email protected]) is managing editor at Buildings magazine.