By Dan Geldermann and Don Sapp

For real property managers who handle large, dispersed portfolios, determining facility conditions and deferred-maintenance (DM) requirements using traditional methods is a significant challenge and major expense. The approach of estimating DM by inspecting facilities and creating detailed job plans with estimated costs for observed problems has remained relatively unchanged for decades. Now, however, there exists a more-efficient method of performing condition assessments and estimating deferred-maintenance needs over traditional methods.

Current Problems

Recurring assessments are a prudent way to benchmark and stay abreast of facility conditions, and they are a building block for developing a needs-based maintenance program. Unfortunately, there are problems with traditional condition assessments:

- They are expensive and time-consuming, with inspection costs ranging from 8 cents per square foot to $1.50 per square foot, depending on the level of detail and degree of sophistication.

- In an effort to reduce assessment costs, many organizations have increased the amount of time that passes between facility inspections by up to 5 years. Stretching the inspection intervals has mismatched the timelines for comparing facilities and installations within a large portfolio.

- From a field perspective, the unknown use of data by headquarters and a lack of any visible funding impact from submissions have fostered a lowering of priority on updating existing data.

- A significant downside to developing detailed estimates for all deficiencies is the limited shelf life of these job plans. After several months, most estimates require a review to incorporate changes that may have occurred; also demoralizing to estimators is the number of completed job plans that are never funded.

- Assessments are not consistently performed from installation to installation - they may be based on differing methods, intervals, and qualifications of personnel performing the assessment. All of these factors leave the headquarters manager and auditors with questions about the validity and timeliness of using available condition data for comparisons between installations.

- To further call into question the usefulness of DM for allocating resources, field inputs have become suspect at headquarters as resource requests for DM seem to ebb and flow with funding climates. When available funding is perceived, DM numbers quickly rise at installations anxious to get their share. Conversely, installations suddenly become well if potential closures are rumored. This has led to a credibility gap of reported results and an uneven playing field between field activities vying for the same resources.

A New Approach

Large agencies should consider another method for accomplishing condition assessments that will return credibility to assessments and reduce the costs necessary to accomplish them. In a successful new approach that addresses condition-assessment problems, the Washington, D.C.-based National Aeronautics and Space Administration (NASA) facilities organization - which is responsible for 44 million square feet of space contained in 5,300 facilities with a current replacement value (CRV) of over $25 billion - worked with Alexandria, VA-based consulting firm Plexus Scientific Corp. to develop a rapid, low-cost, consistent facilities condition system that resulted in a set of useful metrics, including a DM estimate; leveled the playing field by eliminating any biased installation reporting; and reduced the number of detailed cost estimates that are prepared and never used. This assessment method has been developed and refined over several years of field work and independent reviews, and is now used to assess the condition of NASA facilities worldwide.

This approach has been compared against other more-detailed methods by the U.S. Army's Construction Engineering Research Laboratory (CERL), located in Champaign, IL, and reviewed for economic viability by Whitestone Research (with offices in Washington, D.C., and Santa Barbara, CA). CERL confirmed that DM results on test groups were within 10 percent of other more-expensive assessment methods. Whitestone Research provided positive feedback:

- "The primary purpose of the NASA Deferred Maintenance Model is to provide a general measure [of] the condition of individual facilities and an estimate of the current work needs for a large inventory of facilities (based on their conditions). Based on this comparison study, the NASA model performs these functions accurately and efficiently. Because of the high-level assessment focus, it is quick and inexpensive to implement up front. It is an ideal tool for agency planners to create defensible budgets and allocate resources to the installations level. If budget creation is the primary objective of an asset-management plan, then the NASA DM model satisfies this requirement completely." (Engineer Research and Development Center, Construction Engineering Research Laboratory [ERDC-CERL], February 2004).

- "The DM methodology is a promising approach for estimating NASA deferred-maintenance requirements. Its data-collection process and cost-estimation procedure represent significant improvements over established procedures (such as the U.S. Army ISR [Installation Status Report]). The consistency of its ratings in repeated trials is impressive and well documented. The cost-estimation procedure is conceptually sound." (Whitestone Research, July 2002).

The NASA Method provides an appraisal of the general condition of all facilities and an estimate of DM (or recapitalization) costs using a parametric estimating method that costs NASA 2 cents per square foot for each inspection cycle (4-times less expensive than the next most-recognized assessment method in widespread use). The NASA Method was designed to provide consistent, auditable deferred-maintenance estimates at the agency and center levels, and to provide an assessment of the general condition of facilities at the system and facility levels. Each year since 2002, 5,300 NASA facilities around the world have received annual on-site condition assessments during a 60-day period. Intended as a facility-performance metric that can be compared to and trended against other commonly used facility metrics, the assessments have begun to provide performance trends for evaluating the overall effectiveness of facility-maintenance programs. This model is now used to support NASA's annual Accountability Report and to build and justify the agency's annual budget. As an added benefit, the 100-percent review of each facility identifies real property inventory (RPI) record data that appears unusual or incorrect (and that could adversely influence the model results). This has also provided NASA with an on-site review and verification of RPI records, along with a photographic record of its facilities and any significant problems.

Understanding the Process

The condition assessment is a rapid visual inspection of nine different building elements within each facility at an installation. Site visits are conducted using several two-person teams of experienced engineers, architects, and tradesmen who quickly review facilities and systems. Using handheld PDAs, they rate nine building elements for all General Services Administration, Department of Defense (DoD), and NASA facility categories based on ASTM Intl.'s (American Society for Testing and Materials) UNIFORMAT II, Classification for Building Elements. The building elements were ranked from 5 ("excellent," meaning that only normal scheduled maintenance was required) to 1 ("bad," meaning that major repair or replacement was required to restore function, or that the element was unsafe to use). A rating of 0 meant that a system did not exist in a specific facility.

The rated building elements or systems are:

- The structure (foundations, slabs, floors, pavements).

- The roof (roofing, gutters, flashing).

- Exterior finishes (walls, windows, doors).

- Interior finishes (floors, walls, ceilings, doors, stairs).

- Electrical (distribution, lighting, other wiring/controls).

- HVAC (HVAC and other mechanical systems).

- Plumbing (water, sewer, fire-protection piping).

- Conveyance (cranes, elevators, hoisting equipment).

- Program-support equipment (test, research, program equipment)

The parametric DM model was developed using the DoD's Parametric Cost Estimating System (PACES) to determine a percentage value for all nine systems within each facility category. The second step - determining a system percentage of repairs needed for the nine systems based on each of the five condition ratings - was developed from estimated original construction cost using RSMeans CostWorks 2002 Version 6-1 estimating tools. This process of estimating deferred maintenance is designed to be a simplified approach based on existing empirical data in a parametric model.

When field assessments are complete, the ratings are placed into a Microsoft® Access or Sequel Server (SQL) database, where the parametric model converts the assessed condition ratings into three useful metrics: 1) the System Condition Index Rating (SCR), 2) the Facility Condition Index Rating (FCR), and 3) the DM Cost Estimate. All three metrics are capable of providing information in a variety of ways (by systems, by facilities, by type of facilities for sites, and by agency hierarchy) to facilities managers:

- System Condition Index Rating (SCR). SCR is a rating derived from the condition-assessment ratings for each of the nine building systems, such as the structure, electrical, or HVAC systems. The SCR helps a facilities manager determine an installation-wide rating for each building system.

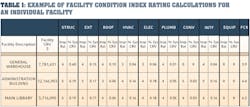

- Facilities Condition Index Rating (FCR). FCR is a simple calculation that weights each of the nine system-condition ratings by its associated system CRV percentage for each of the facility categories and provides a condition value from 1 to 5. In each system, the rating is multiplied by its system CRV percentage to get a weighted SCR. The sum of the nine weighted SCRs equals the facility's FCR. Facilities or systems with a higher CRV contribute more to the overall FCR. Table 1 is a sample calculation for FCR.

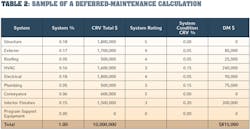

- Deferred Maintenance Cost Estimate (DM). When DM is tracked and trended over time with other basic facility-performance metrics, such as the Annual Cost of Maintenance and Repair or Facility Reliability and/or Facility Availability, the effectiveness of a maintenance and repair program can be evaluated. The DM estimate can be used to determine the traditional Facility Condition Index (FCI), or Condition Index (CI), using DM divided by CRV. Table 2 is an example of the DM calculation.

There are also several useful tools built into the database for facilities managers. First, there are managerial tools that provide basic reports of SCR, FCR, and DM by agency hierarchy and facility category, specifically tailored for the manager's use in developing budget information and prioritizing investment. A second set of options lets an analyst compare individual ratings (SCR, FCR, and DM estimates) from a single system to the entire agency. These tools enable an analyst to perform trend analysis over any sequence or type of assessment for a given time.

Lastly, the database contains a Facilities Incremental Condition Change Model (FICC). This model can help a manager determine the required condition of facilities to meet mission, operations

safety, and human health/comfort issues based on facility-condition goals and a facility's lowest-acceptable condition. It can also aid in determining a DM limit and goal. The model can provide the amount of DM cost per one-tenth incremental increase (or decrease) in a site's facility conditions. This gives a manager an estimate of the cost to increase the condition of a site's facilities by any increment up to a rating of 5, allowing a prioritization of work efforts to return the greatest condition increase with the least amount of expenditure. The parametric DM model is a powerful planning, programming, and budgeting tool.

Wind tunnel rapid equipment assessment at NASA.

The NASA Method is a streamlined condition-assessment technique that is low in cost and consistent across an organization. The assessment ratings produce an array of useful metrics that reflect the condition of both building elements and facilities. The metrics also provide an auditable estimate of deferred-maintenance costs that have proven accurate enough for use in estimating the cost of (and prioritizing) repair/renewal and capital-investment projects within the budgeting process. The method meets the Federal Accounting Standards Advisory Board Standard (FASAB) No. 6 for an annual facilities-condition assessment. FASAB now relies upon deferred maintenance as a tool to reflect the degree of unfunded liability due to an agency's under-funding of facilities maintenance and repair. The method also supports the President's Management Agenda Executive Order 13327 (Federal Real Property Asset Management) and Federal Real Property Council requirements for assessments. This method has saved NASA millions of dollars because it no longer requires the centers to perform costly, detailed, conventional assessments, using up money that could be redirected to maintenance. Facilities professionals who see the benefits of rapid, periodic, validated condition assessments should take a closer look at this approach.

Dan Geldermann ([email protected]) is a facilities management consultant and division manager for the built infrastructure management group at Alexandria, VA-based Plexus Scientific Corp. (www.plexsci.com). Don Sapp worked to develop and implement the NASA Method while he was a Plexus Scientific program manager.