With 57,000 tons of steel columns and beams, 62,000 cubic yards of concrete, 6,400 windows, and 67 elevators in 7 miles of shafts, the Empire State Building is a feat of 20th-century engineering.

10 Little Known Facts About the Empire State Building

from our sister publication interior + sources

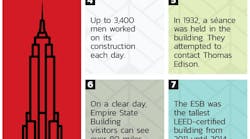

The skyscraper, featuring 2.1 million square feet of rentable office space, opened on May 1, 1931, a mere 20 months after the first signed contracts with architects Shreve, Lamb, and Harmon Associates. Although updates to the systems have been made over the years, many of the original features remain.

“This building was so well-built. The men that built it took such pride in what they were doing, and it was made from first-class materials [with] really great workmanship. We’ve been able to improve on perfection, and have all the amenities of [a] new building,” says Lydia A. Ruth, director of public relations for the Empire State Building Co. LLC, New York City (at the time of this article).

Innovative Construction

“I don’t think you can get a piece of furniture made in a year and 45 days [today],” Ruth acknowledges. So, how was a 102-story building, reaching 1,252 feet into the sky, constructed at a rate of 4.5 stories per week?

In her essay “Building the Empire State,” from her book of the same title, architectural historian Carol Willis cites two reasons for the incredible pace: “A team-design approach that involved the collaboration of the architects, owners, builders, and engineers in planning and problem-solving, and the organizational genius of the general contractors Starrett Brothers & Eken.”

Surprisingly, this design approach was rooted more in practicality and competition than aesthetics. In the era of the skyscraper boom, John Jacob Raskob determined that the Empire State Building should soar above the Chrysler Building, which was under construction at the same time.

Architects had originally designed an 80-story building, but had to alter plans several times to keep up with the Chrysler Building.

Eventually, a mooring mast was devised to add additional height. Intended as a docking station for air blimps, the idea was abandoned after a few failed attempts. Today, the tower of glass, steel, and aluminum is used as the base of the TV tower.

Not even the famous exterior of the Empire State Building was intentional. New York City zoning law required that the building step back as it went up to allow some sunlight to reach the streets underneath the monstrous skyscrapers. Willis quotes contractor Paul Starrett’s autobiography: “In other words, the height, the beauty of the Empire State Building, rose out of strictly practical considerations.”

The “organizational genius” Willis refers to in her essay includes the delivery and transport of building materials. The Empire State Building was built on a previously developed site, housing the original Waldorf=Astoria® Hotel. “There wasn’t any place to store materials, so everything that was delivered had to be built that day,” explains Ruth.

Workers utilized a railway system to push cars full of building materials around the site. To transport the 10 million bricks needed to back up the exterior limestone and metal trim, Starrett Brothers & Eken created an innovative system.

Dump trucks dropped bricks down a chute leading to the basement upon delivery. From there, two brick hoppers, each able to house 20,000 bricks, fed bricks into railway cars for transport to material hoists.

Construction was greatly impacted by the Great Depression. Not only did it provide an available workforce of up to 4,000 men, but it drastically reduced the cost of building. Including land, the total cost of the project was nearly $41 million - $24.7 million of which was the cost of the building itself. In addition to the surplus of workers, according to Ruth, “the winter of 1930-31 was the warmest on record for New York City, so everything was in our favor for record-making construction.”

Innovative Systems

The fact that the building is considered a New York City and National Historic Landmark hasn’t slowed down its progress. In 2011, the Empire State Building was awarded LEED Gold for Existing Buildings certification as further recognition from the $550 million Empire State ReBuilding program. The Empire State Building is the tallest and most well-known building in the U.S. to receive LEED certification.

Read how Pittsburgh is becoming a sustainable city

Ruth acknowledges: “We’ve been able to make improvements on already-great systems and meet the challenges of the 21st century and beyond.”

The fire-detection system in the building has come a long way since 1931. “When the building opened, there were call boxes; they were on every floor, and they made a ‘bong’ sound when manually activated. If [the fire] was on the third floor, it would bong three times so that people would know where [it] was,” explains Ruth. In 1998, a state-of-the-art audio warning and strobe light guidance system was installed.

An FM's Guide to Fire Protection System Inspections

But, much of the building’s solid fire protection stems from the way it was built. “The steel frame of the building was protected by iron oxide and linseed oil paint when it was delivered from the steel mill, and then it was covered with an asphalt coat to resist it from breaking down when it was brought into contact with cement,” Ruth describes. “And, all the steel columns are fireproofed with cinder concrete, so all the steel is encased in concrete, which, of course, makes the building not only strong, but more fireproof.”

How will Steel and Aluminum Tariffs Impact the Buildings Industry?

Left virtually unchanged for 75 years (at the time of this article), the Empire State Building’s water delivery system was an innovation. Unlike most tall New York City buildings, the Empire State Building’s water tanks are inside the building rather than on the roof. Seventy miles of pipe deliver water to the entire building and serve the fire-protection standpipe system.

Replacing 6,400 windows, retrofitting all the light fixtures, converting chiller plants to dual steam and electric usage, and upgrading water pumps has earned the historic building an Environmental Protection Agency ENERGY STAR® rating. More upgrades are on the way, Ruth says, including a computerized HVAC system.

Innovative Changes

Shortly after its opening, the grand building was dubbed the “Empty State Building” in recognition of its early problems with vacancies, including 56 empty floors in 1933. It wasn’t until the end of World War II in the late ‘40s that the building reached full occupancy levels. At the time of this article in 2006, a smaller-scale struggle to fill the building remained. “We [have about] 11- to 12-percent vacancy right now, which, in the real world, [is] not much; but, for us, it is. We’ve usually enjoyed 97- to 98-percent occupancy,” says Ruth. “We’ve been holding back on some vacancies so we can make larger and full-floor spaces available for larger-space users instead of just focusing on small-space users, which was our history here.”

Anne K. Goedken was the new products editor at BUILDINGS magazine.