Even the most well-designed asphalt pavement system can't escape the effects of Mother Nature. Facility owners and managers are often challenged with making financial decisions on how to implement a program that's best suited for their needs. One such need is to lessen the impact of the environmental forces that degrade pavement. Local pavement maintenance contractors can provide guidance on the selection of preventive maintenance menu items, but how do you know what the right option is, and if it's the right time to perform this work? Preventive maintenance strategies that may be appropriate for one situation may not be appropriate for another.

Pavement that is appropriate for preventive maintenance applications includes systems that are relatively new, when preservation of the pavement system remains cost effective. These pavement systems will generally be 3 to 7 years old, and may be experiencing the early stages of deficiencies, such as surface raveling and pavement cracking. Protecting asphalt pavement systems from environmental factors, such as water penetration into the base through cracks and fissures, along with oxidation of the pavement's upper surface, can add years to the life of the pavement system. Preventive maintenance isn't effective for pavement that exhibits structural deficiencies or failures.

As a facility owner or manager, the objective of protecting your pavement investment should start with planning a pavement-management program. The approach for parking-lot-asphalt pavement-management programs should always include cracksealing as a preventive maintenance measure. Crackfilling is one alternative to consider, and it has a distinctly different meaning.

CRACKFILLING

Crackfilling typically refers to the process of blowing out and cleaning cracks prior to installation of a crackfiller material. This is also known as the "blow-and-go" method. If properly done, crackfilling reduces the infiltration of water into the crack, which protects the pavement system from being weakened by moisture. Crackfilling should be used for wider-type, non-working cracks.

Materials for crackfilling can be asphalt emulsions, asphalt cements, fiberized asphalt, or polymer-modified emulsions (listed in the general order of increasing material performance properties and costs).

Life expectancy for crackfilling applications is less than 3 years. This method provides benefits by preventing water intrusion through the crack, which can weaken the aggregate base and subgrade materials. If there are shorter-term expectations and considerations for major pavement rehabilitation in the next few years, crackfilling can be a lower-cost approach that meets these goals.

Multiple applications of coal-tar sealer cause surface-map cracking.

CRACKSEALING

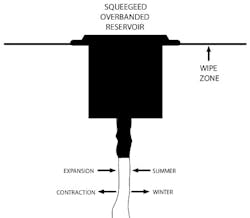

The cracksealing process involves an additional step that's highly recommended for longer-term performance, and involves routing of the crack. Cracksealing includes grinding out the crack to a wider, 0.5-inch by 0.5-inch to 0.75-inch by 0.75-inch square, providing a reservoir for the rubberized crackseal material.

This reservoir provides greater flexibility during thermal changes, especially freeze-thaw cycles. Overbanding the rubberized crackseal material over the top of the crack completes the cracksealing process. Overbanding is sometimes omitted from this process based on local preferences and type of use. If done properly by keeping the thickness of the band less than 0.125 inches in depth, good performance results can be achieved for parking-lot applications.

Materials for cracksealing can be asphalt rubber or rubberized asphalt. Rubberized asphalt materials are the most common, and they're very cost effective. Cracksealing materials are performance graded, meaning that they're designed for specific temperature ranges. Be sure the product is designed for, and has a history of performance in, the climate in which the project is located. Some material products can be identified as "parking-lot-grade" material. Materials such as these can sacrifice long-term performance characteristics for the sake of returning the parking lot to service faster with less tracking of the quicker-setting material. Due to these limitations, don't assume this will be the best product for your needs.

Knowing the distinction of the cracksealing process can add additional life to the pavement while providing further benefits in preventing water intrusion into the system. Life expectancies of 3 to 5 years should be expected for cracksealing applications.

As always, a qualified contractor with a track record of similar successful projects should be used for cracksealing as a first step in implementing a preventive maintenance program. Cracksealing is one of the most cost-effective means of extending the life expectancy of pavement.

As a proactive facility owner or manager, the next obvious question is: "What else can I do to assure that I'm getting the greatest return on my asphalt investment?"

Surface-treatment applications are more complicated than cracksealing; pavement conditions and their end use will influence the type of application. These two issues are further compounded by the climate in which the pavement is located. The fundamental benefit for the application of a surface treatment is to extend the life expectancy and performance of the pavement. It's important to understand the different types of surface treatments, and that it's not the function of a surface treatment to provide any structural improvement.

Cracksealing includes grinding out the crack to provide a wider reservoir for the rubberized crackseal material. This reservoir provides greater flexibility during thermal changes, especially freeze-thaw cycles. Overbanding the rubberized crackseal material over the top of the crack completes the cracksealing process.

SURFACE TREATMENTS

Types of Surface Treatments

There are many surface-treatment options to choose from. General categories of surface treatments include:

-

Coatings (asphalt or coal tar emulsions).

-

Penetrating or rejuvenating sealers.

-

Aggregate-based seals (e.g. slurry seals, chip seals, and micro-surfacing that provide a wearing surface).

Aggregate-based products aren't typically categorized as surface treatments for parking-lot applications. There are many similarities between these groups of products. Due to the coarser aggregate filler content, there are differences in use, application, and performance.

Coating products date back many years with the development of coal tar emulsion coatings. Coal tar is a byproduct of the production of coke from coal. The molecular structure of coal tar gives it the fuel-resistance properties that were desirable. These surface-treatment products were developed to be resistant to petrochemicals and solvents for use in areas susceptible to fuel and oil drippings/spills. The federal government developed requirements for these products for use in aviation applications. The RP-355d requirements are still commonly referred to in the sealing industry today, and the standard has been modified for compliance with ASTM D5727.

Asphalt emulsion coating products are newer to the industry. These products are comprised of hydrocarbon-based bitumen. The molecular structure of asphalt emulsions isn't as resistant to fuel or oil, but modifiers and additives can improve this characteristic. Asphalt emulsion products have an advantage over coal tar in the installation process because fewer odors and less risk of skin burning or irritation occur from asphalt - this is due to the difference in the chemical composition of coal tar and asphalt products.

Rejuvenating or penetrating sealers are products intended to, as the names imply, penetrate and rejuvenate the surface of an asphalt pavement. These materials are asphalt based, blended with water or cutbacks that allow them to soften the surface of the pavement to penetrate the surface layer. This increases the pavement's flexibility, mitigating the impact of environmental aging.

The paved surface (inset) isn't a good candidate for preventive maintenance, unlike the pavement featured in the larger photo.

Installation

Coatings are the most commonly used surface treatment for parking-lot applications. Coating applications are more effective when brushing or squeegee applying the material vs. spray applying since the product is worked into the crevices of the pavement surface; however, there are times when it's not an economically viable option due to the size of the job. Material products and application are critical to performance. There are a number of coating sealers on the market, including modifiers and additives, to increase performance properties.

Fog sealing is a practice used for asphalt emulsions and penetrating sealers. This method involves spray applying through a properly calibrated distributor truck, and is a highly effective means of expediting the installation. This process can result in some variability of coverage, which will affect appearance. Fog sealing must be performed through the use of test strips to assure that frictional properties aren't being compromised. It's also recommended that you sand applications after sealing placements to ensure that a safety issue doesn't result.

This is an example of a newly surface-treated parking lot.

Do They Work?

Managing roads and highways differs greatly from managing a commercial parking lot. Unfortunately, most pavement studies are government funded and focus on roads, highways, and runways/taxiways. Due to the traffic characteristics, surface treatments aren't typically applied on roads or highways, or at airports. Consequently, the industry lacks considerable defined analysis, research, and findings in the coating and rejuvenating field, although advancements continue to be made to close this gap.

When asked if surface treatments are appropriate for use at a facility, first determine the objective. Surface treatments, especially coatings, work well in improving the aesthetics of a pavement that's the "front door" to a facility. If an attractive, black-surfaced parking lot is the sole objective, almost any coating product can achieve this goal.

Be cautious of subsequent applications of coatings or penetrating sealers until they've reached the end of their useful lives. If the amount of residual material is significant, reduction in surface friction can create a safety hazard and impact the pavement condition (see the photo at the top of this article), because surface-map cracking will occur. Again, you may want to consider a sand application after sealing placements to ensure that a safety issue isn't created.

Millions of gallons of coatings and sealer products are applied annually in the United States, and the number of contractors who perform this work is in the thousands. Products, or variations of products, likely range in the hundreds, to be conservative. In addition, installation methods can vary, as can the different conditions/geographies of the pavement. A product that works in one situation may not be appropriate for another. Products and contractor qualifications are critical to a successful project.

As with cracksealing, for the best economic value, applications of surface treatments should be performed only when pavement is relatively new and in good condition. The oxidative aging of asphalt pavement begins at the time of construction and continues through the pavement's life. The greatest rate of oxidation, however, occurs within the first few years. Implementation of a surface treatment has the potential to reduce the impact of environmental aging of the pavement, mitigate the impact of surface raveling, and fill hairline cracks that are too small for cracksealing.

In some situations, using these products may make significant wear obvious (which can be variable) within the first 12 months, especially in the snowbelt region. Roadways, drives, and aisles in parking lots have a tendency to wear much faster than parking stalls. If you choose to use these products to improve the aesthetics of your pavement, the frequency and cost of future applications will increase. The lives of these products vary, but general expectations will be approximately 3 years.

Staying aware of your existing pavement and providing a means to protect these assets should remain high priorities.

Steve Schmidt is vice president, pavement consulting division, at Cedar Rapids, IA-based Benchmark Inc., a national roof and pavement consulting firm.