Variable refrigerant flow (VRF) technology is underutilized and unfamiliar to many in the U.S. But given its energy-saving potential and easy installation and maintenance, it’s one you’ll want to get familiar with.

Invented in Japan, VRF systems have been around for almost three decades and are widely used in Asia, Europe, and South America. Introduced in the U.S. almost 10 years ago, VRF systems are still relatively unknown.

Related: Smart Sensor Technology: Reducing HVAC Energy Use

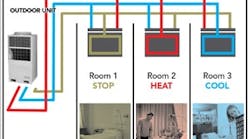

Traditional systems turn on and off depending on whether the room is too cool or warm, but VRF constantly modulates refrigerant temperature. By varying ventilation speeds, VRF units work only at the needed rate, consuming less energy than on/off systems even though they run more frequently.

The Best Fits for VRF

The potential of VRF technology is maximized in buildings with multiple zones – such as hospitals, hotels, and offices – due to its ease of customization and ability to pinpoint areas, says Marc Zipfel, director of product marketing for Mitsubishi Electric.

Rush Health Systems recently implemented a Mitsubishi VRF system for the maternity ward on the 45,555-square-foot third floor of the Rush Foundation Hospital in Meridian, MS.

“I had nothing but problems of people being too hot or too cold, and I had a 34-year-old, 500-ton chiller running at 98% capacity,” says Fred Rogers, vice president and chief resource officer at the hospital. “I thought, ‘There’s got to be a better way.’”

On topic: How to Pay for Energy Upgrades

The facility now utilizes VRF for the third floor in conjunction with the old chiller, which still serves the rest of the hospital. This system is efficient because it takes the entire third floor’s load off of the overworked 500-ton unit, he says.

Installation was easy because Rogers could renovate one of the floor’s wings at a time with virtually no disruption to operations.

“I’ll knock on my desk right now, because to this point I’ve had no maintenance issues since it was completed in 2009,” he says, adding that so far he has only needed to clean coils and change filters. “They’ve just hummed along.”

VRF systems are also a good option for facilities with space restrictions, says Kevin McNamara, vice president of commercial air conditioning for LG Electronics USA. Smaller supply lines replace ducts and don’t compromise existing structures or require complicated space considerations. Likewise, all VRF modules are managed from a single control system, eliminating lost lease space like mechanical rooms, McNamara adds.

Savings and Benefits of VRF

Rogers says the new VRF system operates at about 81% capacity, a big difference compared to his prior system which ran close to peak load. This has resulted in substantial savings.

Another way to save: Smart Grid Initiative: Financial Benefits for Building Owners

“I estimate we’ve saved about $36,000 per year in energy reduction just from one job on one floor,” says Rogers, adding that he has already installed smaller units throughout the rest of the campus. Two critical access, 25-bed hospitals were recently built and 75-80% of the new facilities are cooled and heated with VRF, he estimates.

“Since I put them in, I haven’t had anyone call me complaining they’re too hot or too cold,” Rogers adds. “Now they can do what they want.”

Aside from the benefit of user comfort, another is that VRF produces sound levels as low as 58 dBA, McNamara notes, adding that air circulating inside is louder than the outside unit.

“It can really help building owners, operators, and tenants have a much better building experience,” says McNamara.

VRF is accepted and implemented worldwide, so it’s not a question of whether the technology is viable, he stresses. It is more an issue of being open to new mindsets.

“Early adopters looking for an edge against older designs will reap that many more benefits in the future,” McNamara says.

Chris Curtland was assistant editor of BUILDINGS.

Two hand-picked articles to read next: